This blog has been co-authored by Gary Wong, OSIsoft, Nick Wiley, Casne Engineering, and Dave Cox, FirmoGraphs.

The Resilient Water Utility

U.S. water, wastewater, and stormwater utilities have been working for years towards a more resilient future. As customers, we see the evidence of this in the fact that day in and day out, we turn on our taps and receive clean drinking water. We flush our toilets and know that the waste is handled safely and efficiently.

Over the past several years, the focus on resiliency among utilities has been with respect to extreme weather events (droughts, floods, wildfires) and terrorist attacks (cyber, physical). But it is in times of crisis, such as the current COVID-19 pandemic, that assumptions are challenged, and preparedness and resiliency is tested. Opportunities to improve become evident.

Being a leading utility involves viewing available technologies from the perspective of maximizing resilience rather than simply a necessary cost to be minimized. Smaller utilities already have fewer resources, so the right mix of technology and service partners can help them become much more efficient and reliable in good times, and more adaptable during a crisis. Utility personnel often bear the brunt of crises at a significant personal cost. As we have seen with the current pandemic, staff are challenged to maintain operations through social distancing measures, some having to remain onsite and away from their families.

There is a better way, and a big part of the solution involves Operational Technology (OT) which enables automation, remote monitoring, and data-driven action. OT projects can be implemented in ways which provide short-term quick wins and long-term incremental improvement, provide operational visibility across critical operating parameters (such as flows, pressures, water quality, and potential upsets) from home, and minimize complexities and distractions when there is a need for focus, and enhance situational awareness through real-time analysis.

Resiliency & The Regulatory Framework

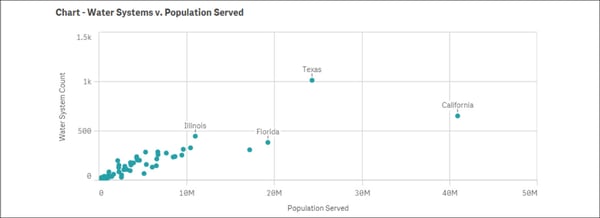

As reported by FirmoGraphs in their blog America’s Water Infrastructure Act published on January 7, 2019, the America’s Water Infrastructure Act required Risk and Resilience Assessments for all community water systems serving populations greater than 3,300, impacting over 9,200 drinking water systems nationwide. The following is a chart showing the total population served, and the total number of water systems, per state.

The assessments are quite broad, including:

- Risks from malevolent acts, such as terrorism

- Risks from natural hazards, such as earthquake or flood

- Physical asset resilience, such as pipes and treatment facilities

- Electronic asset resilience, including computers and other automated systems

- Chemical handling and storage

- System operation and maintenance

Optimizing Plant Operations With Limited Staff

Many water and wastewater treatment plants run with lean staffing even during normal times. In emergency situations, continuous and efficient operations are even more critical. Today, efficient operations rely on real-time and historical data from multiple data systems.

A recent WaterWorld.com interview regarding operations during the pandemic, including George Hawkins (Former DC Water CEO) and Andy Kricun (former CEO of Camden County Municipal Utilities Authority), drove home interesting points about resiliency (see Water System Resiliency in the Wake of COVID-19). Some key takeaways include:

- Utility staff, and their families, are impacted by the virus. It’s going to be more challenging to spread out the staff and make sure that they are around for the duration of this crisis.

- All utilities are trained to be thinking in terms of being leaner and more efficient. In this instance, utilities need to think a little bit differently through this crisis to make sure that redundancy is more important and so that we may ask more people, more supplies and maybe over-order of that because of the uncertainty.

Reducing Risk With Remote Monitoring

In the water industry, many critical infrastructure assets are remote and unmanned. There are dozens of examples of unmanned assets, from raw water intakes to booster stations to entire plants. Water and wastewater systems are, by necessity, geographically distributed and it is normal for maintenance and operation teams to cover many square miles of distributed assets.

In the water industry, many critical infrastructure assets are remote and unmanned. There are dozens of examples of unmanned assets, from raw water intakes to booster stations to entire plants. Water and wastewater systems are, by necessity, geographically distributed and it is normal for maintenance and operation teams to cover many square miles of distributed assets.

Implementing and having automation, remote sensors, and Internet of Things (IoT) devices to measure water quality, water levels, consumption, flow, pressures etc., provide essential operational visibility and situational awareness. Without these sensors, one wouldn’t know what is happening in the process.

A great example is Colorado Springs Utilities (CSU) where they had learned from past experience that water quality, flows, and pressures were needed in key areas if wildfires were to occur. They could continuously monitor the situation remotely from any device, including personal laptops and phones, to ensure fire fighters and people had the water they needed to fight fires. Without these sensors, staff had to risk their own safety by driving in close proximity to fires in order to observe the situation. For a short and informative video about CSU, follow this link.

Financial Resiliency In A Post-COVID World

As reported by Raftelis on behalf of the American Water Works Association (AWWA) and the Association of Metropolitan Water Agencies (AMWA), drinking water utilities across the U.S. are experiencing revenue and cost impacts associated with the COVID-19 crisis. See the “Financial Impact of the COVID-19 Crisis on U.S. Drinking Water Utilities”, April 14, 2020. The financial effects will

be felt for years to come, with anticipated impacts approaching 17%. The same will apply for wastewater utilities suffering the loss of ratepayer payments and stormwater utilities whose federal and municipal funding sources are under duress due to a loss of tax revenue.

There was already very little financial ‘play’ in the system. Many utilities simply will not have available funds for ‘extra’ expenses. They will need to optimize their revenue and institute strong operational controls to stretch available dollars. Real-time information systems help optimize ratepayer billing experience in normal times and this applies even more-strongly during upsets. Leveraging smart meter technology to measure real-time consumption and leaks in the water distribution network and large commercial and industrial customers can maximize revenue.

Call To Action

The full effects of the current pandemic are not yet understood, but it is clear that Operational Technology (OT) will play a central part in the water industry’s management of the operational and financial challenges that are already upon us. The critical missions of delivering safe drinking water and waste disposal depend on the industry’s ability to maintain maximum resilience, both in good times and during the unexpected. The COVID-19 crisis is a wake-up call for many utilities who have not yet embraced digital transformation in their operations, either due to a lack of awareness, perceived risks, or questions around justification. The current pandemic provides a key opportunity for all critical operations to assess their true resilience and employ already-proven technologies and methods to fill gaps.

For example:

- The challenges associated with a rapid shift to remote operations is probably more clear now than ever before. Is secure remote access to SCADA and other operational data available? If so, is it easily and quickly accessible and scalable? Do other stakeholders, beyond operators, have the necessary operational visibility to support the mission? Are new or improved camera systems needed to provide visual inspection of key areas in order to maintain safe operations from afar? Are there issues to be addressed in maintaining regulatory compliance or quality testing?

- New Industrial Internet of Things (IIoT) sensors and solutions that provide process monitoring in real-time to provide situational awareness never seen before in water quality and the distribution and collection systems.

- Equipment monitoring and performance analysis can help make informed decisions about which components should be stocked on-site (spare pumps, seals, or other parts) in the event that supply chain problems during a crisis prevent timely access to these items.

- Current work-from-home orders provide a unique opportunity to study peak demand scenarios and system capacity issues which would not be evident during normal times.

In all of these examples, the key enabler is secure, reliable, accessible, and flexible digitization of real time operations - a digital twin, if you will. One thing that is clear is that operational resilience is within reach for any organization, regardless of size or internal skills - if there is commitment. Selecting the right OT solution and service partners will help accelerate progress, achieve success, and prepare us for the next unknown crisis that comes our way.

Comments