Unless it's a check for a million dollars, few people like surprises. If you are planning for your first Arc Flash Analysis or preparing to switch to a new consultant to perform the next one, it's crucial to know what to expect.

By now, most facilities have performed their initial analysis. By Code, subsequent studies occur every five years or after changes have been made to the system. As you prepare for your facility's next Arc Flash Analysis, here is what you can expect.

Discovery

The first step in the analysis is the discovery phase. Our team will complete a field investigation of the designated site or building. We begin with a review of the equipment documentation on record and understand how the power system is currently operated. Following this, we conduct field surveys to either verify or determine all components installed. The information gathered includes equipment make and model, AIC/withstand ratings, and cable sizes and lengths. To ensure accuracy, we review the existing data and then compare it to our team's measurements during the field investigation. Once all information has been deemed accurate, our team can proceed to the next step.

We start the process with many of our clients using the information from previous Arc Flash calculations. Some clients have existing models that have been kept and updated for several years. However, in comparing our findings with the existing documentation, the team found various discrepancies, placing the results of the previous analyses in question. These examples underscore the importance of a practiced, diligent approach to the discovery phase.

Analysis & Adjustments

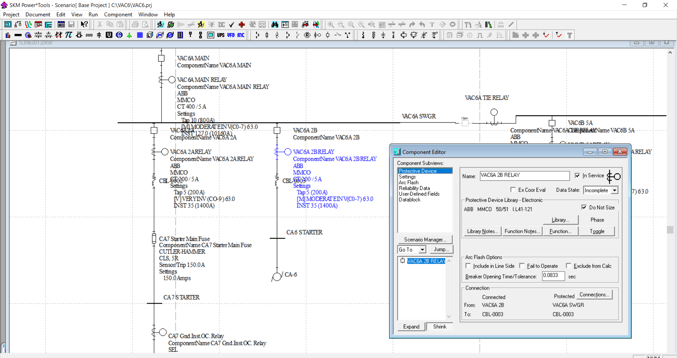

Once our team has completed the field investigation, we will begin building a model. We use specialized software that is designed to take the data collected to build the power system model.

Once the model is built, our engineers begin to analyze the electrical system's performance under various conditions. Through the software, we create a set of potential scenarios that may occur within the real world. The software allows us to identify areas where these scenarios' results may have negative impacts on the equipment.

Our in-depth analysis includes:

- Protective Device Settings

- Coordination Between Devices

- Available Fault Current

- Damage Curve on Equipment and Conductors

- The Effects of the Results have on Arc Flash Hazard Levels

After analyzing the potential impacts of the events, our engineers modify the model to develop recommendations for the client. These recommendations may include adjusting the equipment or protective devices and changing the PPE an employee wears. Additionally, our team will analyze potential equipment upgrades for a facility to get into compliance.

Final Report with Recommendations

The last phase of the process is the Final Report. The report will include a summary of the work performed, our findings, and most importantly, recommendations to address any reliability or compliance issues. Supporting documentation will include the schematic of the overall system, protective device coordination curves, arc flash results and label data, and the model's electronic source file.

In many cases, Casne is contracted to assist with the recommended equipment upgrades. Once the upgrades are complete, the analysis is rerun to depict the final field conditions. We then provide the updated labels to the facility and support the labels' application to all the equipment. Your facility is now in compliance, and you can check that item off of your list.

Having a trusted consultant like Casne Engineering to ensure you are in compliance will take the stress and work off of you. With over 40 years of success in professional engineering and technology integration services for critical industrial facilities, we develop and support engineered solutions using the best of breed products and technologies to complete Arc Flash Analysis across multiple industries. Contact us here to schedule a time to talk with our team.

Comments